Coffee Roasters

Coffee roasting machines

Balcells has a wide range of coffee roasters depending on the needs of each customer.

- Roasters machines designed for “Gourmet” roasting coffee.

- Industrial coffee roasters for small, medium and large productions.

- Industrial coffee roasters for roasted coffee for small and medium productions.

- Industrial coffee roasters for small, medium and large production ” Mixed “.

In all our range of roasters we have semi-automatic and automatic models.

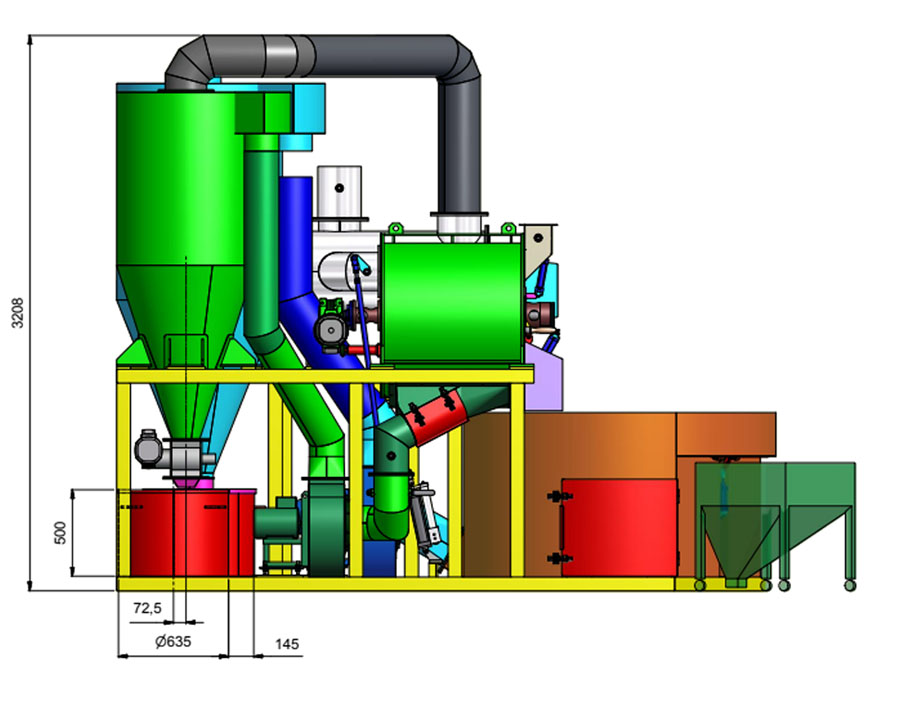

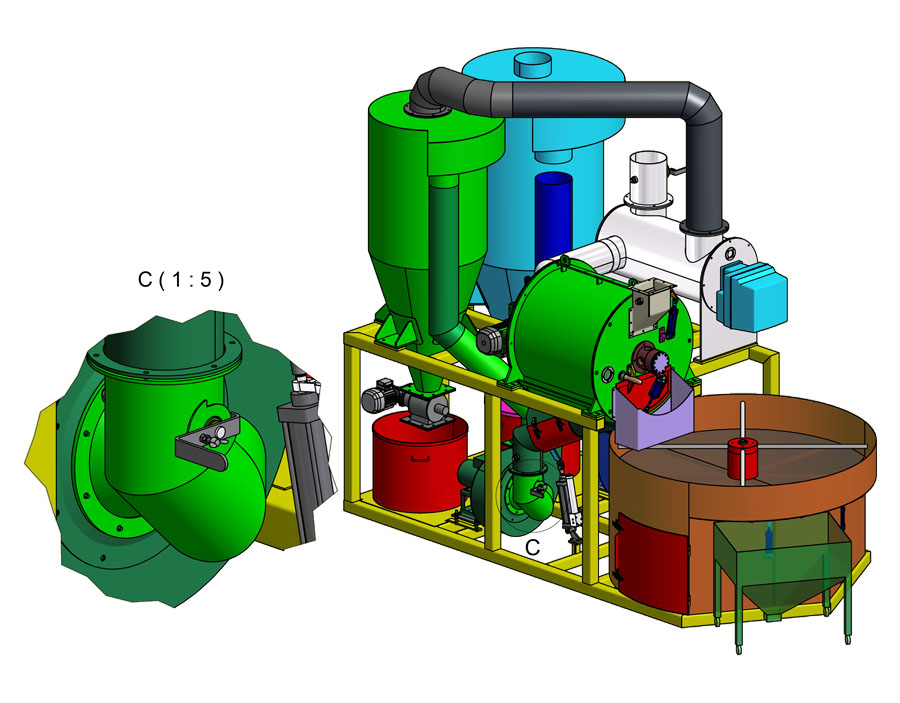

Industrial roasters for natural coffee

BTR models

We have both fully automatic operation and semi-automatic roasters for natural coffee.

For small, medium and large production.

Equipped by:

- Smoke recycling system for energy saving.

- Perforated interior drum system.

- Separate combustion chamber.

- Air regulation system in the drum and motor-fan

- Touch screen and PLC for fully automatic operation.

- Curves for the desired roasting profile (up to 22 steps).

- Modular combustion burner.

- Pneumatic transport for loading green coffee (optional). (Opcional)

- Stone remover for roasting machine (Opcional)

- Colour options to choose from.

Due to its technical characteristics and design, it allows the following products to be produced with excellent quality and presentation:

- NATURAL ROASTED COFFEE

- ROASTED COFFEE

- COFFEE SUBSTITUTES

- CEREALS AND SEEDS

- SUNFLOWERS

- PISTACHIOS

- PEANUTS IN SHELL

- ALMOND

- HAZELNUTS

- COCOA AND OTHER PRODUCTS.

Roaster´s machines for roasted coffee, nuts, cocoa, cereals and seeds.

The VTM (Mixed) roasters have been designed in the market taking into account the existing needs of the roasting industry in terms of space, energy saving, ease of assembly, performance and diversity of products, quality and presentation..

Equipped by :

- Smoke recycling system for energy saving.

- Perforated inside drum system for the upper drum.

- Closed drum system for the lower drum.

- Separate combustion chamber for the upper drum.

- Separate combustion chamber for the drums.

- Solid state sugar or salt injector system.

- Water and suggar or sal injector.

- Automatic regulation of drum air and motor-fan.

- Touch screen and PLC for automatic operation.

- Curves for the desired roasting profile (up to 22 steps).

- Modular combustion or 2 flames for liquid or gaseous gas.

- Pneumatic transport for loading green coffee.

- (Opcional) Stone remover for roasting machine

- (Opcional) Synthetic enamel and parts in refractory stainless steel.

- Control parts, chrome-plated and stainless steel.

Its main characteristics are :

- Very reduced installation space.

- Easy to transport.

- Easy assembly.

- Easy handling.

- Energy saving

- Savings in waste.

- Product quality and presentation.

Download the catalog of mixed roasters for natural and roasted coffee · VTM series

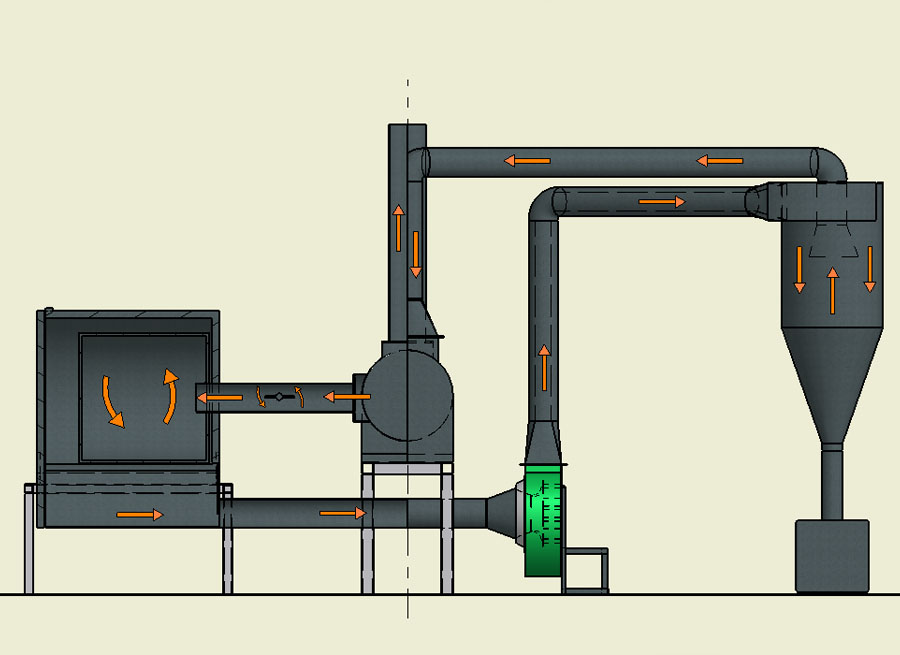

Balcells Roasting System

Our roasters work by “Convection”.

This system occurs when heat is transmitted from a hot solid to a fluid or vice versa from a hot fluid to a solid.

A fluid surrounding a heat source will heat up in the layers closest to the source, which decrease in density and rise, transporting the heat taken from the source to other layers. In turn, cold portions of the fluid replace those that have been heated, establishing currents of hot and cold fluid, known as convection. Conversely, a hot fluid in motion, when it comes into contact with the surface of a body at a lower temperature, will give up part of its heat to the body. This is natural convection and when it is activated by mechanical agitation it is called forced convection.

Balcells roasting system thermal transmission by conduction makes it possible to obtain

- Homogeneity in the roasting.

- The coffee beans and derivatives are roasted uniformly without burning the ends of the beans or preventing the beans from being raw inside and very roasted on the outside.

- Control of the speed and quantity of air flow into the roasting drum

Do you need more info?

If you need more information, fill out the form and we will contact you as soon as possible.