More and more we are confronted with stricter environmental regulations.

Depending on the country or location of the coffee roasting industry, the values of these regulations change. Depending on the proximity or location of the industry it is mandatory to install a system to completely eliminate dust particles in terms of smoke emission into the atmosphere.

We have several suitable options depending on the circumstances of each client.

Smoke burners

By means of the smoke burner system, we clean the gases from the roasting process before they are released into the atmosphere.

By means of an ascending helicoidal system, the smoke passes in front of the flame, achieving a burning of the smoke. A smoke burner usually operates at a temperature of 180 o C.

The smoke burner consists of three levels, through which the smoke is recirculated.

-

- On the first burner level, the smoke from combustion enters the burner and rotates in a direction favourable to the projection of the flame, which favours its centrifugation so that the smoke can pass to the second level.

- In the second level, the maximum temperature, the smoke burner is raised to the maximum temperature (approximately 700 o C).

- Finally, on the third level, the spinning is cut off to optimise the entire cross-section towards the outlet pipe.

The temperatures increase according to the roasting phases and depending on the results of the heat source and the output of particles travelling with the smoke to the outside.

The combustion chamber is constructed with a high temperature material and thermal insulation. The burner type is usually a two-flame burner.

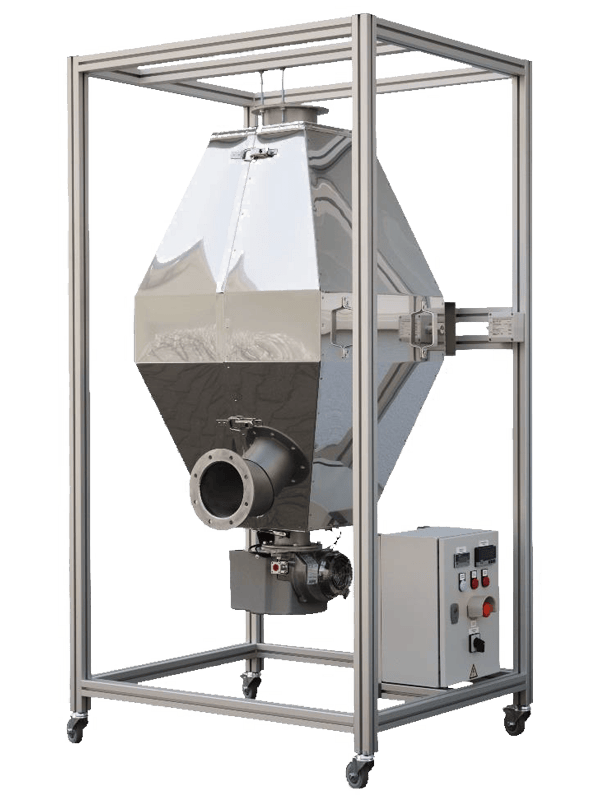

Heat exchanger

At Balcells we have designed our own heat exchanger.

The objective is to avoid the mixture of gases generated by combustion with the product itself during the roasting process. This system guarantees a product without combustion odours generated by Gas or Gas-Oil and other types of combustion.

The heat exchanger is composed of a separate combustion chamber for the hot fluid (combustion) and a special patented design that allows heat recovery.

The components generated in the combustion chamber pass through a special set of tubes which transfer the heat to be transported to the outside. Through a fan, the ambient air is moved to the side of the combustion chamber, which has the dual function of absorbing the heat and insulating it. The heated air is then transported to the clean area of the heat exchanger, where, due to the Venturi effect of the flow, it absorbs the heat necessary to carry out the roasting process, transmitting it to the product inside the drum.

The burner regulation system and temperature control is carried out by means of a PLC which controls the heat exchanger valves.

The combustion chamber is constructed with a high temperature material and thermal insulation. The burner type is usually a two-flame burner.

Catalytic converters for the coffee industry

Balcells offers a new solution specially designed for the needs of small, medium and large coffee roasters.

This allows you to comply with all defined environmental protection limits and reduce energy consumption.ía.

We guarantee a reduction of volatile organic compounds, hydrocarbons that are present in a gaseous state at normal ambient temperature or are very volatile at normal ambient temperature.

Reduction of nitrogen oxides (mg/Nm3).

This system also allows the isolation of odours during the coffee roasting process.

At Balcells we are always committed to the environment and energy efficiency.

Balcells accessories brochures

We have a large number of accessories for an industrial coffee plant that may be of interest to you. Download the attached PDF’s and discover all that we can do for your production line.

Call us at (+34) 670 396 781 and we will respond quickly, or use this FORM and we will contact you:

If there is an accessory that you need and you cannot find it in the pdf’s, please fill out the form to request more information.

Contact Us

Do you need more info?

If you need more information, fill out the form and we will contact you as soon as possible.