Automation for coffee roasters

Balcells offers the possibility of automating complete installations, as well as roasting machines, silos with weighing control, formulations and work histories.

We study and develop all the customer’s needs in order to be able to offer him his automation project in his installations and in a personalised way.

Why Automate your Installation or Machinery?

Due to new technological advances, automating and updating the automation process of an installation and existing machinery allows basically three advantages:

- Complete and efficient control of the production process.

- More specific maintenance.

- More efficient technical service and control of the installation.

- Actualización a las Normas de Seguridad en el proceso de trabajo.

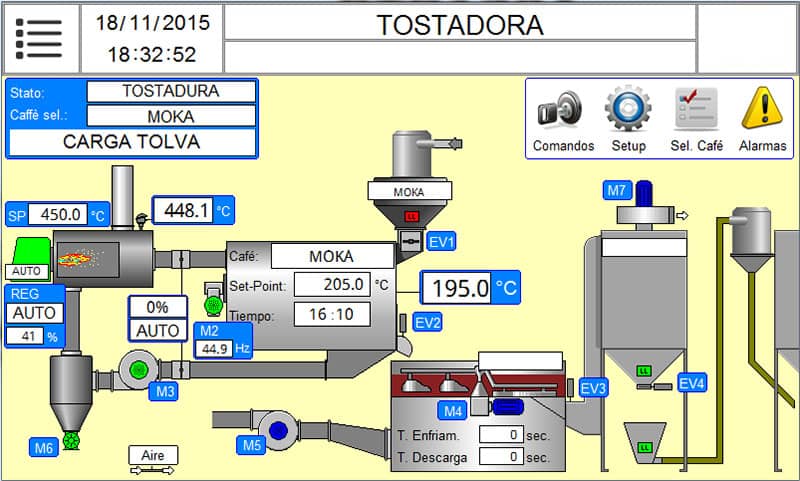

Automatic Roasting System

We install a PLC Programmable Logic Controller in which we install the programme customized by Balcells, which allows different roasting profiles to be obtained without the need for the operator to do them manually.

During the roasting process, the roaster develops its own roasting curve, adjusting itself automatically to achieve the chosen type of roast by means of automatic self-regulation.

We can develop different roasting profiles, each one of them self-regulating the roasting machine and adjusting to its own roasting profile.

This profile is saved in a history so that it can be reused in the next roasting cycle or a new roasting profile can be created.

The software that we integrate to the roaster or coffee installation is developed by Balcells, which is freely accessible and useable by the client. It does not require any type of license.

Technical Assistance and Maintenance.

This incorporates technical assistance to the customer byEthernet, a system that allows a problem to be solved quickly and efficiently without the need for a technician to travel, avoiding technician costs and ensuring that the toaster is down for as little time as possible

The installed software allows the customer to be always updated and with the option of constant maintenance.

By means of “Wi-fi” it allows us to visualize and control the machine remotely through a PC, mobile phone or Tablet.

Our Profile Roasting Systems:

Profile Roasting Basic

Roasting curves in manual mode:

By means of a potentiometer we control the modulating energy source and generate the curve live. This type of recipe is stored in an Excel file in which we can make the formulations and the history automatically and use them.

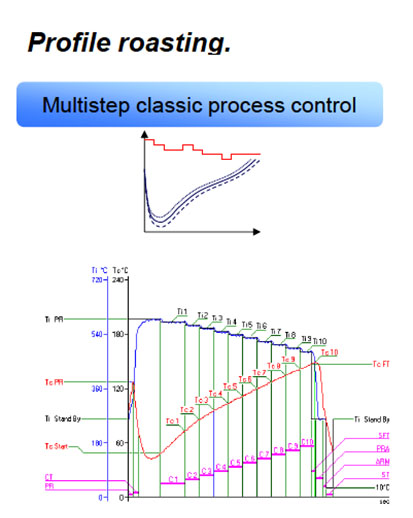

Profile Roasting Super

Roasting curves in automatic mode:

Once the ideal roasting profiles have been engraved, the machine is able to reproduce the chosen profile and achieve exactly the same end product, even if changing the amount of product introduced, the outside temperature, the temperature of the green product automatically.

Do you need more info?

If you need more information, fill out the form and we will contact you as soon as possible.