Process

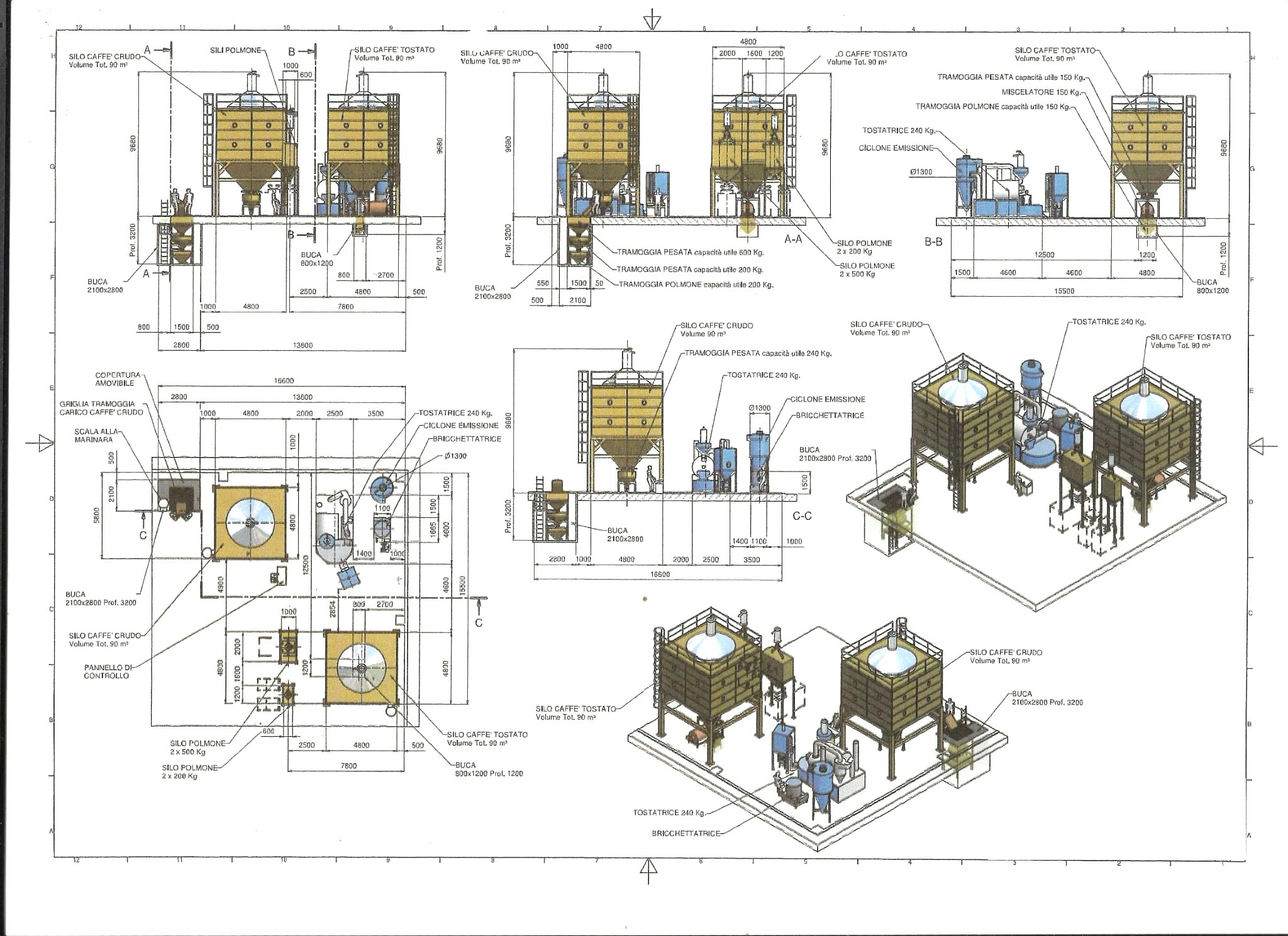

We develop the design process in our own Technical Office in a personalised way for each type of client in the hands of a team with a long experience in the sector and a high level of training.

In order to be able to develop it well, we start with a technical visit to the client where we outline all the technical data necessary for the development and manufacture of the project.

Study of the location of the machinery This allows us to offer the customer the best option for the installation (Heights, distances, weights, service lines) At present we have introduced the service of advice to our customers in terms of safety regulations and environmental standards for our specific customers according to the country or province where the machinery is installed.

Then our Technical Office, called (T.O.), develops the project of the installation. For this purpose, we use the latest generation 3-D design programmes

In this process we take into account the following data : Productions, most suitable transport systems depending on whether it is green coffee and types of green coffee, roasting taking into account the roasting point of each client, ground coffee taking into account the process of degassing and type of grinding.

The next step is the Packaging Process, for this the type of coffee that is going to be packaged, the type of Package that is going to be made and the formats to be produced are taken into account.

Next, we study what we call “end of line” if the package, once packaged, is presented shrink-wrapped, boxed, or other options.

Finally, the project is presented to the customer together with its economic valuation and, if the customer approves, we proceed to manufacture it

Before the delivery of the machinery, we have created what we call FAT The customer is invited to our factory to verify and test the machinery before delivery. This system allows us to simplify the problems that may exist during the assembly and start-up of the machinery at the customer’s premises, avoiding a bad image and simplifying the assembly and start-up .

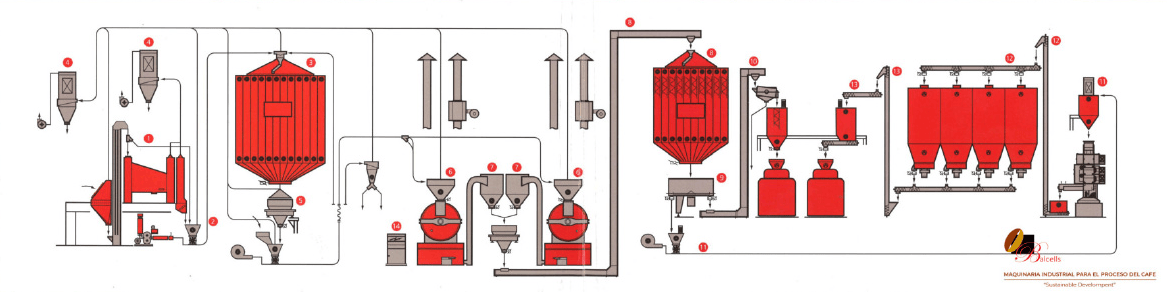

Process of a cofee instalation

We are a company with a long history and experience in the world of machinery for the roasting industry

We have a “Key-Board” for our customers in which we can offer them a wide range of machinery, from specialized coffee shops to fully automated installations for medium and large productions.

1. Hopper loading and pre-cleaning of green coffee

2. Pneumatic conveying of silo or roaster loads

3. Green coffee storage silo

4. Coffee dust cleaning filters

5. Coffee weighing group

6. Roaster´s

7. Stone remover with weighing control

8. Silo loading and storage of roasted coffee.

9. Pneumatic conveying of silo or roaster loads.

10. Loading of roasted coffee bean silos for packaging.

11. Pneumatic loading and grinding of coffee beans.

12. Loading transport of gas elimination silos.

13. Loading of ground coffee silos for packaging.

14. Electric control panel with the possibility of a computer.

Here you can understand the whole process from the arrival of the green coffee to its packaging.

1º When we receive the green coffee, it is advisable that it undergoes a cleaning and selection of the green coffee beans. This is achieved by means of machines called Limpias, densimetric tables or optical sorters.

2º Once the green coffee has been cleaned and selected, it is transported by means of a “Venturi” system or other systems. The important thing is that this type of transport is fast and avoids downtime in production

3º This transport takes the green coffee to the green coffee silos where it is stored and classified according to the varieties or “Blends” of each client.

4º In order to avoid dust during transport, it is important to install a system of filters or cyclones to collect dust.

5º In the green coffee silos, a weighing system is installed that allows us to unload the coffee from the silo according to the desired or formulated quantities”. It is possible to unload it by origins or blends ” depending on each type of customer.

6º By means of another transport system ” Venturi ” or ” Vacum ” the coffee is taken to the roasting machine where the coffee is roasted. At this stage, the performance/production of the roasting machine/roasters is studied.

7º Once the coffee has been roasted, a “stone remover” or “deschinadora” is installed to collect any foreign bodies from the coffee that may have remained, such as stones, nails, etc.

Under the stone remover a weighing device is installed which allows us to know the loss of the coffee (The difference between the weight of the green coffee that has entered and the weight of the roasted coffee).

8º Once the coffee has been roasted, it is transported to the roasting silos. This type of transport is very delicate as we have to prevent the coffee from breaking during transport. We have systems such as “Vacuum”, “Chain-vey”, “Buckets”, depending on the type of project. Through this transport the roasted coffee is stored in its silo and is classified according to the varieties or “Blends” of each client.

The roasting silos are not only important for the installation. They have the task of preventing “coffee oxidation”. Oxygen is an enemy for roasted coffee during its “sweating process”, if this process is done inside a silo in which the coffee has no outside oxygen, its sweating process is correct.

9º Under the roasting silo there is a mixing machine that allows the roasted coffee to be mixed correctly. This mixer, by means of its rotating system and interior blades, allows us to blend the coffee uniformly.

Depending on the project, another transport system is installed at the exit of the mixing machine, also taking into account that roasted coffee is very fragile and depending on the origin and roasting point, some will be more or less fragile than others, the roasted coffee is transported to its corresponding packaging machine for coffee beans.

10º If you want to produce ground coffee, a special transport for ground coffee is installed from the mixing machine. At this point, the type of transport can be “endless” or “empty”. It is not so important that the coffee is broken, as it will be unloaded to the mill, but obviously if it can be avoided, it is much better.

The grinder for ground coffee can be of different systems depending on the type of grinding we want to achieve. Strawberry mills, Roller mills, Conical mills, etc

It is important that the grinder allows us to achieve a homogeneous grind and that during this process it does not transmit heat to the coffee.

12º The ground coffee is transported by a special conveyor so as not to mix the different types of grindings that have been made Normally the most suitable system is by “suction-vacuum” although other systems exist. Depending on the production, distances, etc., the most suitable system is chosen for each client.

The ground coffee is transported to silos for ground coffee. hese silos have to be well manufactured and designed for the process of “degassing” of the coffee and to be able to obtain a degassing in the correct time.

13º Once the coffee has been degassed, it would be transported to its corresponding machine for the Packaging of Ground Coffee, Vacuum Packing Machine for ground coffee, lines for the packaging of Pods and Pads or Encapsulation Lines

Design, manufacture and marketing of machinery for the roasting industry.

Types of coffee silos

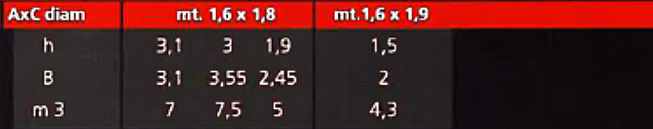

In these tables you will be able to discover sizes and capacities of standard and customised silos.

¿Do you need a custom/size silo?

If you need a custom silo, fill in the form and we will contact you as soon as possible.

Round silos for green or raw coffee

Square modular silos for roasted coffee

Round silos for roasted coffee

Silos for ground coffee